Containerised Incinerator TDR

Haat’s range of incinerators include stand-alone units, skid mounted units as well as containerized units. Skid mounted and containerized units are invariably chosen where capacity of the equipment is not very high. The containerized model TDR is chosen primarily to enable movement of the incinerator from one place to another and these units can be connected either to a mobile generator or AC supply at site.

Containerized units enable location of the incinerator, fuel tank, control panel, etc. in one container (subject to size) making it easy to move and operate. The TDR model can also be supplied with air pollution control equipment like dust collectors, scrubbers, etc.

When combined with air pollution control equipment, the incinerator is offered with an ID fan to create the necessary negative pressure in the chamber. If the system is offered without air pollution control equipment, an ejector mechanism can be supplied to create negative pressure.

Burners can be based on diesel, gas or other fuels depending on the availability of these at the final destination. The entire system consisting of incinerator, fuel tank, scrubber etc. can be a fully automated system if required. TDR model incinerators can be used for many types of wastes including general garbage, bio-medical, hazardous waste,

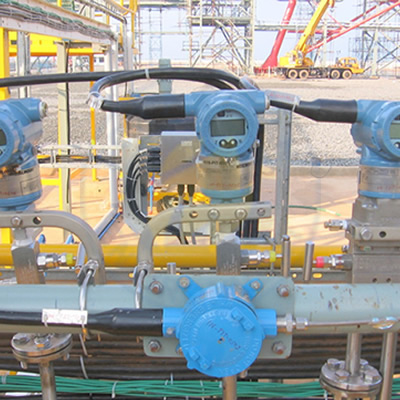

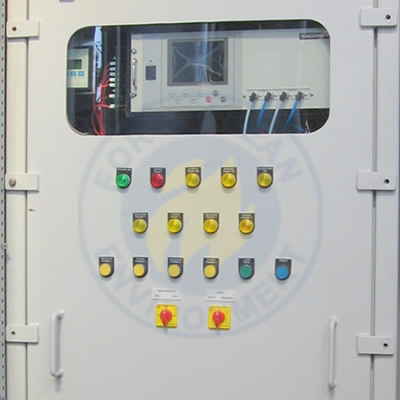

The system can be equipped with instrumentation and automation including PLC and HMI. Loading system can be a hydraulic ram loader and de-ashing can be with a similar hydraulically operated ash pusher. The refractory used is high quality low cement, high alumina which achieves high strength at high temperature in excess of 1000°C, making it stronger as it is used and completely reliable and long lasting. Refractory being the backbone of an incinerator system, its reliability and life are of paramount importance for the incinerator. The designs of the ram loader and ash pusher are time-tested and well proven over the past many years.

The equipment is designed for a minimum life of 15 years.

3D modelling is done for all customized TDR models to facilitate movement of personnel inside the container and operation of the various parts of the system. This helps us to implement the concept `Design for Maintainability’.

Haat has supplied quite a number of containerized systems for the following applications;

- narcotics and drugs

- biomedical waste

- hazardous waste

- general garbage

- camp waste

The TDR model is chosen by large users like the United Nations because of its compactness and reliability, portability and ease of operation.

Incinerator with scrubber and 30-m chimney installed by HAAT has been working satisfactorily since June 1999 in our factory. We use it for disposing of paint sludge - Mr. Pankaj Tyagi, New Holland Tractors (India) Pvt. Ltd., Noida.