Model OXR – Thermal Oxidizer

A Direct Fired Thermal Oxidizer (DFTO) is designed to destroy Volatile Organic Compounds (VOCs) and Hazardous Air Pollutant (HAPs) which are produced during chemical processes and found in exhaust systems of industries.

The DFTO destroys the emissions containing VOCs and HAPs by the process of combustion.

The Thermal Oxidization process works at a temperature of 1000°C or higher at which the chemical bonds that are holding the molecules together are broken. The VOCs are converted to combinations of carbon dioxide (CO2), water (H2O) and thermal energy by the high temperature of the combustion process.

The DFTO is a widely used abatement system for chemical processes producing exhaust streams with high levels of pollutants. It can achieve more than 99% hydrocarbon destruction rate (DRE). The combustion chamber initiates the ignition of the process with a help of a pilot burner. If the VOC laden gas is able to take over from the pilot burner, then no additional fuel is required to run the system.

Combustion air is also introduced to the chamber for an effective combustion, which enables retaining the process stream at the operating temperature in order to achieve the desired DRE. In other words, residence time is also a key to achieve this

The application for DFTOs exists in;

- Chemical processing

- Refineries

- Natural gas

- Oil and gas

- Waste water treatment

Haat’s design of DFTOs features the following special advantages;

- Fabrication of very high standard by welders qualified under ASME Sec. IX

- Strong quality control department to ensure adherence to customer requirements, specifications and our own inspection and testing plans

- Special castable refractory which achieves high strength at high temperature thereby eliminating possibility of refractory damage

- Exclusive surface preparation and painting process which provides long paint life

- Trusted and tested burners of international makes

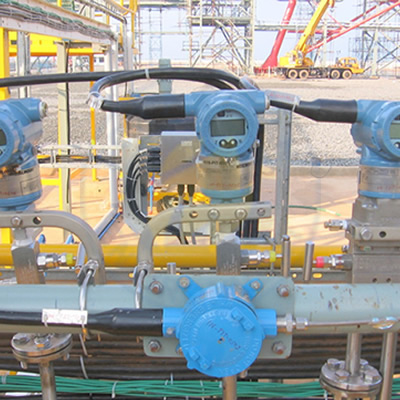

- High end instrumentation

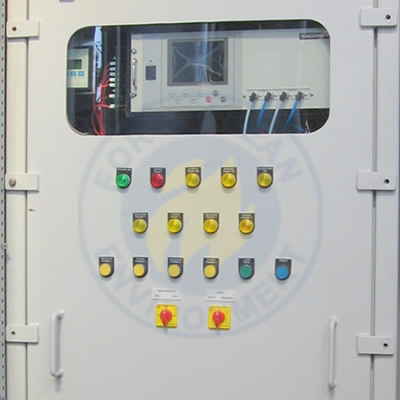

- PLC and HMI to enable fully automatic operation

- Special safety features in-built into the system

- Ejector mechanism to cool outgoing flue gas and to create negative pressure in the chamber

- Recovery of heat by steam generation using waste heat

Haat has supplied their OXR thermal oxidizer DFTO in India and abroad to many industries and these are functioning to the satisfaction of the users. A video of a SIL 3 rated system can be seen on this page.

“The incinerator project included a high level of Quality Assurance, Third Party Inspection and comprehensive documentation which was adhered to.” – HOD (CPP & Utilities), Reliance Industries Limited.