Among the various models of incinerators and thermal oxidisers available in Haat`s range, the Animal Cremator (ACR) is a work horse because it can be operated continuously and is built for different types of animals for incineration of sheep, deer, pigs, cattle, zebras, horses, ponies, quartered beasts and even larger ones like oxen, cattle, camels and baby elephants.

Incineration capacities and maximum weight acceptances can be customised to specific requirements.

The most common method of disposal of the animal waste is deep burial or open burning. Compared to these primitive methods, incineration has been found to be the safest and best. It ensures complete burning of the waste, reducing the volume of waste considerably, leaving only a small portion of ash. Incineration ensures there is no infection caused by the dead animals and in places like zoological parks, the safety of the other live animals is ensured.

Incineration, combined with air pollution control equipment, provides full environmental safety. There are many different types of air pollution control equipment available, depending on the emission standards to be met.

The incinerator system that is offered has many unique features which offer advantages to the end user:

1. Built ruggedly of IS 2062 or ASTM A 36 or other suitable ASTM grade steel, it is provided with enough volume considering the maximum weight acceptance of the chamber and the burning rate of the carcass.

2. The ACR incinerator is designed with a primary combustion chamber for the carcass burning and a secondary combustion chamber for burning the products of combustion.

3. Sufficient volume is provided in the primary chamber and the secondary chamber volume is calculated based on the residence time of the flue gas, which at present is 2 secs.

4. This is a dual hearth design with the primary hearth for receiving the dead animal. The hearth is made of a special refractory material with high strength at high temperatures. It is very strong both at room temperature and at 1000°C and makes it more than adequate in terms of strength to handle the designed weight acceptance.

5. The secondary hearth is designed to burn fat which is released from the dead animal as it is being incinerated. This is very important, as otherwise, there is a strong likelihood of the liquid fat running thru the ash door and other openings, making things messy.

6. The lining of the chambers is with a combination of castable refractory and bricks.

7. Burners are provided both in the primary and secondary chambers. They may operate with diesel or gas as fuel, as per availability. The burners could be 2-stage or modulating.

8. An FD fan is part of the configuration and this provides the necessary combustion air to the chambers.

9. The charging of the dead animal into the chamber is thru a large charging door which is operated either by electricity or hydraulically because of its weight.

10. For smaller animals, the charging could be thru a ram loader.

11. Some mechanized lifting equipment will be necessary to lift the carcass and charge it to the cremator. This could be a forklift or a jib crane or an overhead crane or an electric winch, depending on the requirements. Even if the animal is fed through a ram loader / feeder, lifting equipment is needed to place the animal into the charging hopper.

12. The air pollution control equipment that is normally offered with the ACR is the wet venturi scrubber with its accompanying down-stream equipment, in line with the current Bio-medical waste rules.

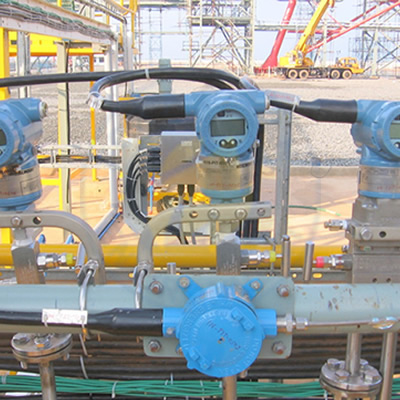

13. The scrubber is followed by an ID fan and tall rubber-lined stack with its accessories such as aviation lamp, lightning arrestor, sampling port, etc (only if applicable). Stack

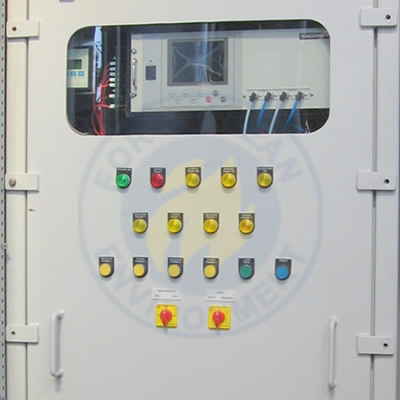

14. It is preferable to have the controls thru a PLC based control panel with HMI screen for automatic operation of the whole system.

Standard equipment:

• Primary combustion chamber

• Secondary Combustion chamber

• FD fan

• Manual charging door

• Fat burning arrangement

• Burners

• Diesel tank

• Standard chimney

• Control panel

Optional equipment:

• Automatic charging arrangement

• Mechanised loading using ram loader/jib crane/overhead crane/electric winch

• Emergency stack

• Wet/Semi dry scrubber

• ID fan

• 30 metre rubber-lined stack

• PLC control panel

• Piping & Cabling (within battery limits)

• Refractory lined and rubber lined ducting

• Heat recovery

• Auto de-ashing

• Emission monitoring system

Advantages:

• Proven design

• Trouble free operation

• Special refractory with no maintenance

• Long equipment life

• Fully automatic operation

• High quality fabrication

• Time tested refractory materials

• Special preparation and painting

• Multiple optional equipment

The model ACR animal incinerator / cremator can be used conveniently with the help of the many optional equipment available.

Automatic charging is done using a large door which is operated electrically / pneumatically / hydraulically with very little or no manual intervention, This is important considering the door is rather large to accommodate large dead animals and is heavy.

The loading of the dead animal can be done easily using either a jib crane or an overhead crane or even an electric winch. The choice of the optional equipment is determined by the size and weight of the animal.

When adding air pollution control equipment, it is necessary to install the emergency stack, which vents out hot flue gas thru it, thus saving the expensive downstream equipment from high temperature during fan/pump tripping or power failure.

There are quite a few choices available for the air pollution control equipment, starting from a wet venturi scrubber to gas cooler, acid gas scrubber, bag filter, demister/mist eliminator etc. The configuration can be decided based on the emissions desired.

ID fan and tall stacks are required with the stack being rubber lined to prevent wear due to corrosion. The MOC of the fan is invariably stainless steel of suitable grade because the flue gas does carry a certain amount of moisture.

The entire incinerator operation can be made fully automatic, once the animal is charged, with the help of a PLC control panel. The operation and control philosophy will decide the PLC configuration. Addition of a HMI interface will further aid in making the controls easy to manoeuvre.

Heat recovery and auto de-ashing are further options available.

Either a Continuous Emission Monitoring System or a portable one can be offered, depending on the rules and requirement.

Applications in:

• Animal houses

• Veterinary establishments

• Zoological parks

• Animal husbandry

• Abattoirs

• Animal quarantines

• National parks

The Haat ACR animal incinerators / cremators are in use in India and abroad for quite some time and have helped users resolve the difficult problem of disposal of dead animals safely and satisfactorily.

“We thank Haat for their professional conduct during the execution of this order.” – Praful Dhokai, GM, Clyde Equipment, Fiji.