JSW Steel Plant is located in Toranagallu in the Ballari-Hospet iron ore belt in the State of Karnataka, India. It is a fully Integrated Stee...

JSW Steel Plant is located in Toranagallu in the Ballari-Hospet iron ore belt in the State of Karnataka, India. It is a fully Integrated Steel Plant well connected to sea ports. It has an installed capacity of 18 million tonnes per annum, has a low carbon footprint, uses a different methodology of coke oven gas for power generation as well as for the production of pellets. It is considered the World’s Sixth Largest Steel Plant.

JSW Steel, Tornagallu is the first Indian steel plant to use the Corex technology to produce hot metal. This technology remained untested until JSW took it upon itself as a challenge. Corex is an environmentally friendly process for the production of hot metal from iron ore with low grade Fe content and low grade coal. It is smelting-reduction process. In the conventional blast furnace, direct use of the low grade coal cannot be made, thereby the Corex process eliminates the need for the coke making process. The Corex process reduces NOx gas emission using oxygen in its place making it both cost effective and eco-friendly.

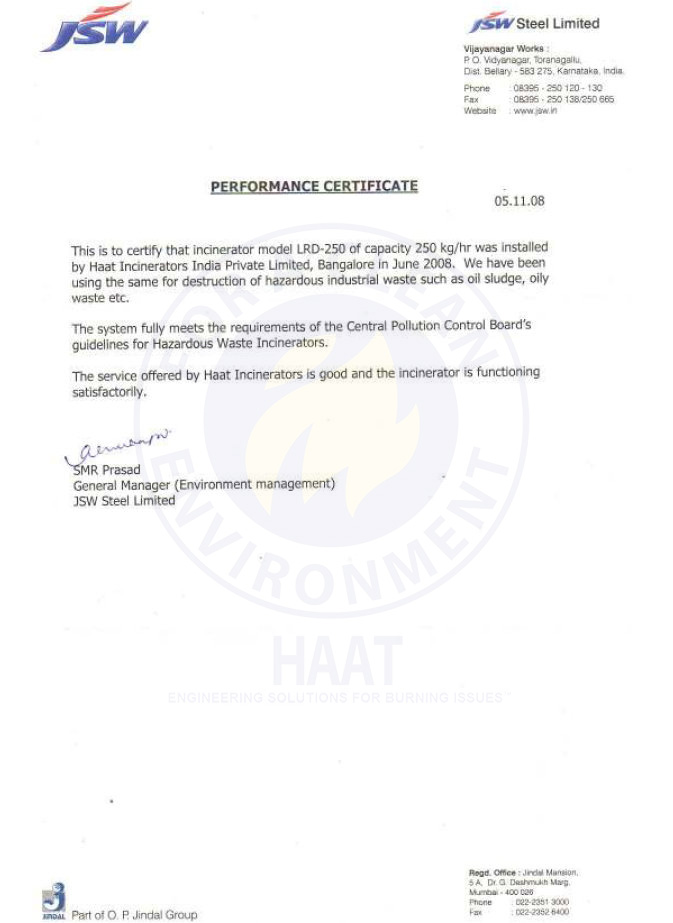

From this prestigious plant, we got an RFQ for a hazardous waste incinerator of 250 kg/h with appropriate air pollution control equipment and 30 metre chimney. The waste in this instance was used oil and oily sludge from the cold rolling mills.

Three companies were shortlisted for this prestigious project and Haat was finally chosen as the successful bidder after various stages of evaluation and discussion. The decision was

We supplied our LRD -250 model incinerator with an Air Pollution Control System for this application with ram loader, PLC control panel, 30 metre stack and required instrumentation.

The special feature of this installation is the use of Corex gas as fuel for the incinerator also. The Corex process reduces NOx gas emission using oxygen in its place. The main component of this gas is carbon monoxide and H2. Corex gas has a low calorific value of 2000 Kcal/Nm3. Although the gas has a low calorific value, considering the fact that the use of this gas reduces the carbon footprint, contributing to a better environment, JSW requested Haat to procure a burner system capable to handle Corex gas. Normally any fuel with this kind of low calorific value is difficult to use. However taking this as challenge Haat worked with burner manufacturers in Sweden and Italy and got specially made burners for this application.

The system was installed and commissioned to the satisfaction of the users in the year 2008.

“Incinerator is in our service since April 1997. The incinerator is working satisfactorily in accordance with the specifications” - Mr. R. Anbalagan, Manager (Process), Mitocon Biotec, Cuddalore.