Haat has a system of continual improvements and we have been continuously upgrading our incineration technology from simple units which were first taken up in the '90s. We are now in a position to offer systems which not only comply, but exceed the requirements of Euro / US-EPA norms.

Haat has a tie-up with CTU (Clean Technology Universe), Switzerland for an advanced range of incinerators and air pollution control equipment.

Haat also has a tie-up with Mercodor, Germany for their wide range of shredders.

Our in-house Research and Development and Design teams have focussed and developed their capabilities on;

• Combustion calculations

• Thermodynamics, mass and energy balance

• Heat transfer, refractories and insulation

• Emission control – wet and dry

• Incinerators for specialized wastes including radioactive (NORM waste) incinerators and precious metal recovery incinerators.

• Oil and gas incinerator packages for very tough and stringent applications like offshore / onshore usage

• Pharmaceutical waste incinerator package

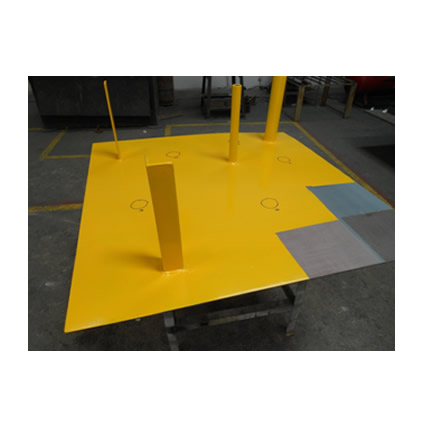

• Fabrication techniques complying with ASME standards

• Surface preparation and painting complying with standards such as SSPC and NACE

• Quality assurance including hydro test, NDE, noise testing, vibration testing, COG, etc.

• Hazardous area applications

• High-end instrumentation for complete automation

• Continuous emission monitoring systems

• PLC process control

" The incinerator is functioning extremely well and meeting all the requirements of Gazette of India notification. The Strength of the equipment lies in its easy handling, economy in treating bio-medical waste and meeting all criteria control test of PCB Karnataka "

- Group Capt. H. S. R. Arora, Registrar, Command Hospital Air Force, Bangalore.