The confectionery industry consists of a group of large companies in the world that produces various types of chocolates, chewing gum and candy as ...

The confectionery industry consists of a group of large companies in the world that produces various types of chocolates, chewing gum and candy as well as other products made from cocoa. Cadbury, Nestlé and Hershey’s are the leaders in this multi-billion dollar industry. This industry continues to grow each year despite economic conditions, employs over 500,000 workers in thousands of factories around the world, and produces about 3.2 billion kg of these products each year.

The food and confectionery industry in India enjoys a consistent growth in its business, thanks to the growing population and the preference for packaged snacks. The confectionery industry in India which was ranked 25th in the world in 2009 has now emerged as one of the largest and most well developed food processing sectors in the country. This is facilitated by a growing Indian economy, encouraging many multinational companies to invest in India’s confectionery market.

The Indian confectionery market is going through rapid changes due also to the trends in consumer behavior. The industry benefited not only from the economic boom but also due to the growth in consumer spending, thanks to the new-found Mall culture and changing life style.

The market for confectionary products are chocolates, sugar and gum products. Sugar based confectioneries include hot boiled candies or toffees which are quite popular. Apart from chocolates, sugar boiled confectionery is mostly consumed among children and a huge market for chocolates exists. In addition to this, manufacture of cupcakes, birthday cakes, etc.

It is to be noted that the industry also generates a substantial amount of wastes in the process of manufacturing the end products. In the case of bakery industry the wastes include egg shells, spoiled eggs, packaging materials, expired bakery products, etc. Cakes with tarts, pastries, pops, buns and sandwiches are unsalable after 24 hours. In the case of chocolate, its making produces process wastes, packing waste, fats, oils, syrups, candy, fruits, dust and powders. They also include expired chocolates and candies as well as the finished product that fall under conveyors onto the floor during packaging.

While some of these wastes can be converted into fertilizer through composting, manufacturers prefer to dispose of them by incineration as they do not wish to create a secondary market for unscrupulous duplicators.

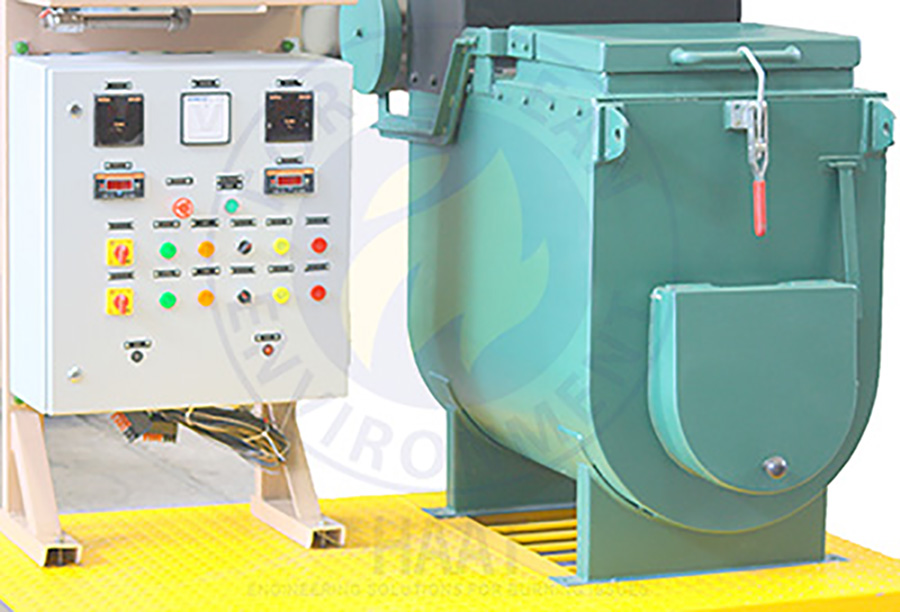

Haat has supplied incinerators model PD, BP and ADR for these applications successfully over the past many years. The manufacturers include many big names of the industry in India and abroad.

Some of these systems are working for more than 15 years and the users are quite happy.

" The incinerator at the International Hospital Of Bahrain is working very well. Indeed it is a smokeless incinerator without causing any pollution"

- Dr. Praful L. Vaidya, Head of Surgical Dept. & Equipment Committee Chairman, International Hospital of Bahrain.